Splitting machine

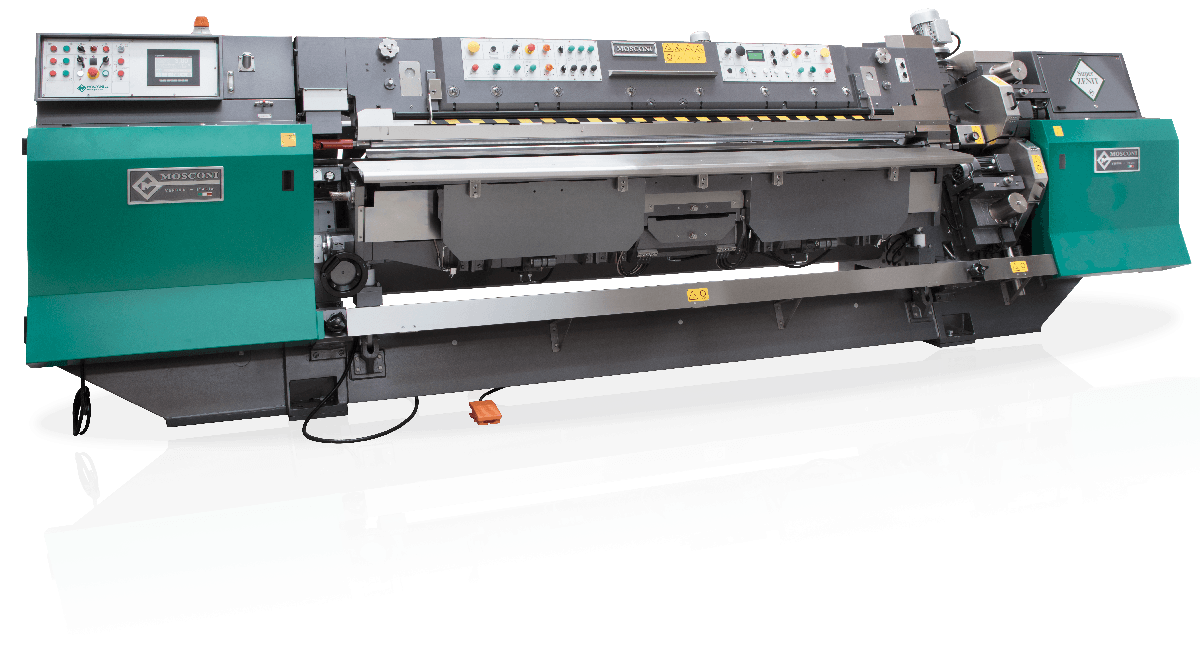

The new Mosconi Super Zenit Evolution splitting machine is the result of a series of innovations and improvements, designed and tested to strengthen the structural, functional and operational performance. The precision and high performance of this machine for splitting hides, as the high productivity, reliability and reduced maintenance, are its strengths and the best guarantee of a safe, lasting and advantageous investment. This splitting machine is available in the lime-split and wet-blue version.

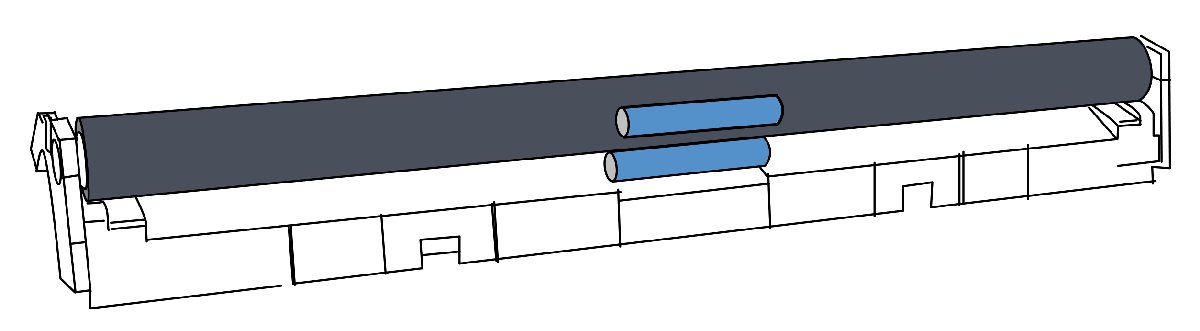

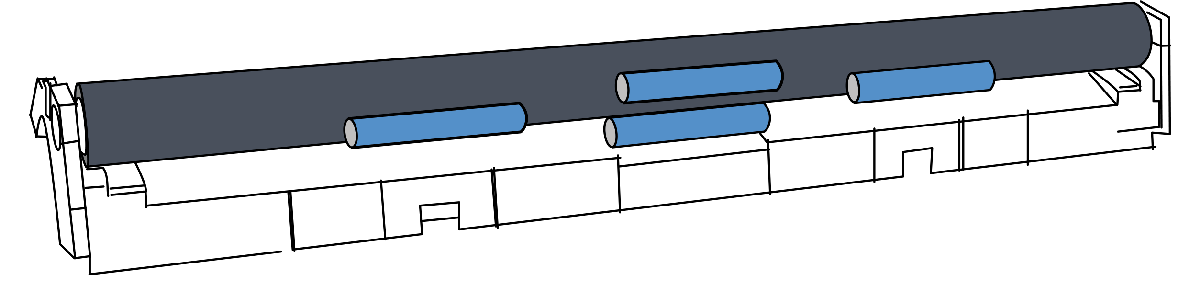

The counter-roller unit (in the lime-split version) contrasts the bending of the rubber-coated cylinder with independent adjustments.

Splitting machine

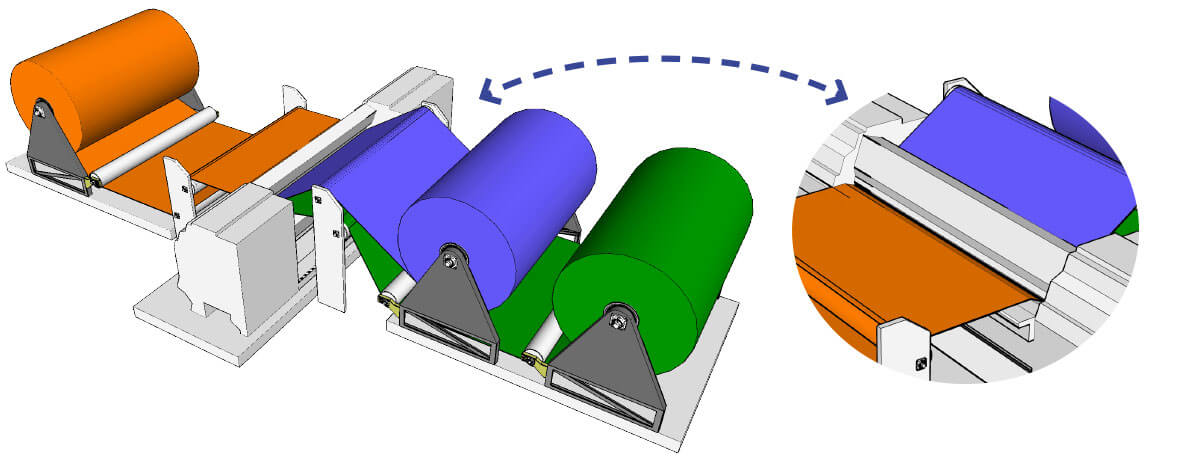

The wet-blue version provides an automatic introducer, the motorisation of the joint movement of head and bench with reading of the movement on a display, and the bilateral split outfeed belt. The application of the regulator motorisation can be combined with a rear measurement bridge.

The double counter roller unit, applied in the central area, allows the limited use of the “brackets” only on the side parts of the traction roller (where there is less wear), therefore reducing the maintenance and adjustment operations.

and synthetic materials

Splitting synthetic materials like non-woven fabric, is a plausible configuration of the machine, with accessories at the infeed and outfeed for continuous splitting.

The grinders are operated by rotating spindle motors on pairs of high-precision bearings, supported by a robust cast iron structure. A calculated inclination of the sliding guides allows the cutting angle to be kept constant, set to the gradual reduction of the diameter of the grinders. The automatic devices for the micrometric progress of them and of the “detach/attach” control, are electric (direct current motors). The grinding groups are protected by a STAINLESS-STEEL cover in the lime-split version.

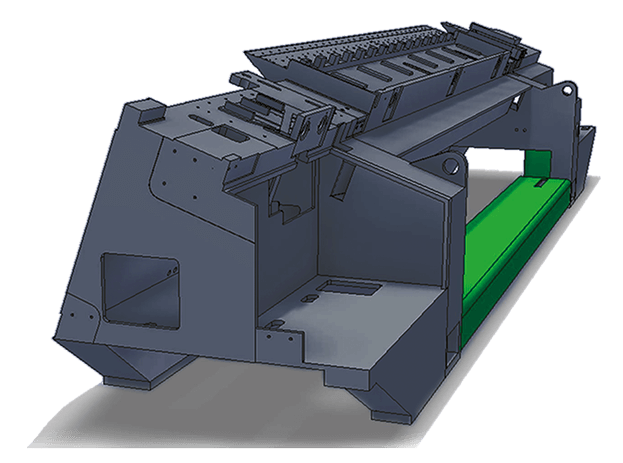

The new structure of a crosspiece, brackets, table and contrast roller supports, all in heat treated cast iron, gives increased bending resistance. The adjustment of the lower longitudinal unit occurs through screw jacks.

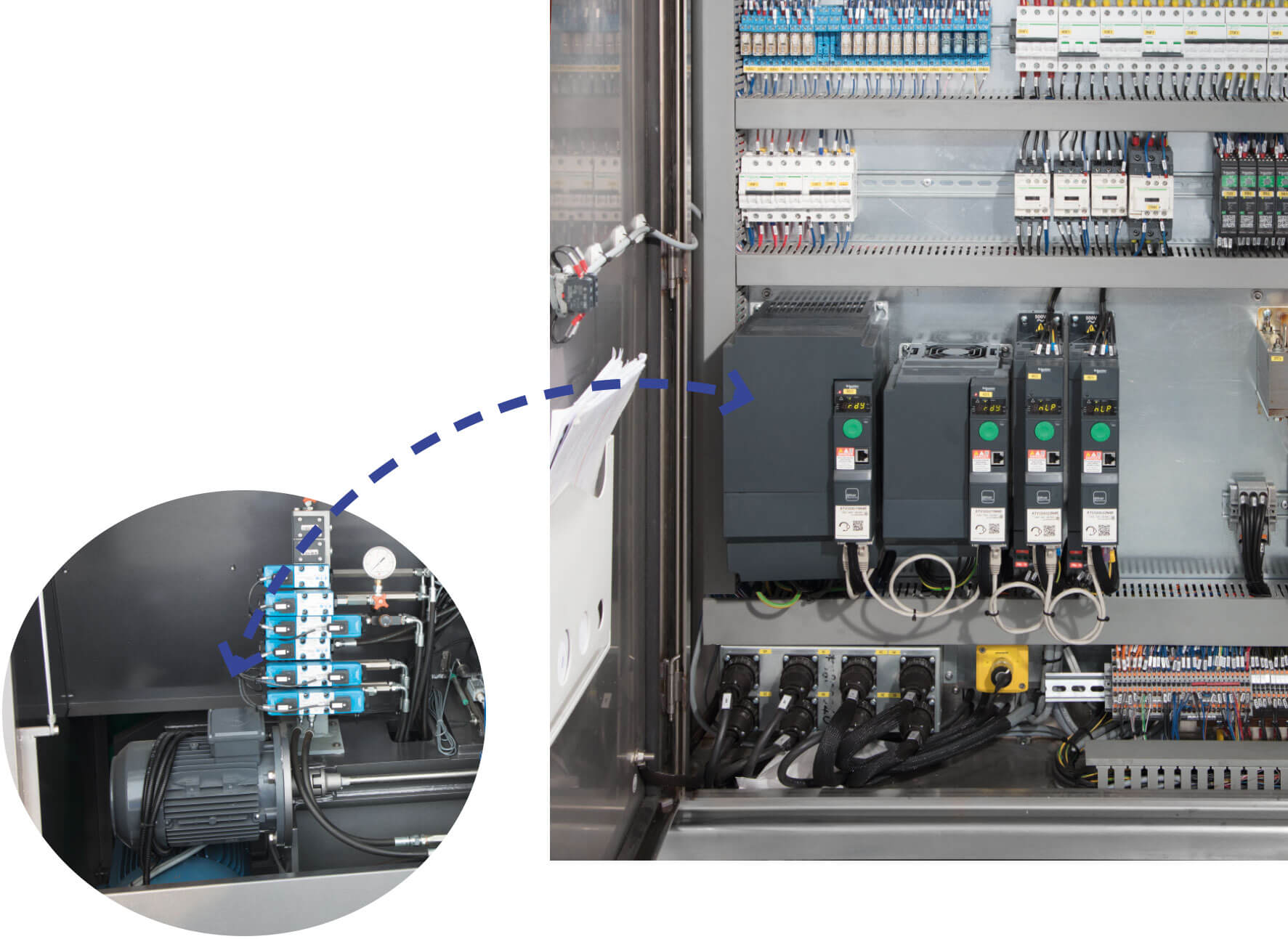

The Super Zenit Evolution splitting machine was created from an innovative project and is made of cast iron with high resistance to bending and stabilised through heat treatment. The thickness search is achieved through a precision device in electrically operated oil bath. The recovery of any wear is hydraulic. The centesimal variation of the thickness is controlled by an encoder and visualised on a digital display. The quick opening and closing movement is hydraulic, with an automatic return to the pre-set thickness.

For the operator’s safety in the tannery, in the Super Zenit Evolution splitting machine there are:

The control panel is easy to understand and has an automatic hide counting device.

| SUPER ZENIT EVOLUTION | 2300* | 3000 | 3200 | 3250* | 3300 | 3600 | ||

|---|---|---|---|---|---|---|---|---|

| Working width | mm | 2300 | 3000 | 3200 | 3250 | 3300 | 3600 | |

| Length | mm | 5560 | 6250 | 6450 | 6450 | 6450 | 6760 | |

| Width | mm | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | |

| Height | mm | 1740 | 1740 | 1740 | 1740 | 1740 | 1740 | |

| Maximum installed power - 50 Hz | kW | WB | 25 | 25 | 25 | 25 | 28 | 28 |

| TR | 30 | 30 | 30 | 30 | 30 | 30 | ||

| Maximum installed power - 60 Hz | kW | WB | 30 | 30 | 30 | 30 | 33 | 33 |

| TR | 36 | 36 | 36 | 36 | 36 | 36 | ||

| Net weight | kg | 9500 | 10200 | 10500 | 10600 | 10700 | 11000 | |

| * On request | ||||||||

Upon customer request, Mosconi spa regulator motorisation in the wet blue/dry version and the programmable motorisation of the longitudinal bench for the lime-split version. It is also possible to request the remote assistance service.

Find out about the optionals!